1. White cast iron. The cutting of white cast iron is bright white, so it is called white cast iron. The carbon element exists in the form of a permeable carbon body. This kind of carbon is hard and brittle, which is difficult to process, so it is less used in industry. Therefore, it is a suitable raw material for steel making and forging cast iron.

2. Gray cast iron. Its cut is grey. Most of the internal carbon is flake graphite. This kind of cast iron is widely used in some castings and wear-resistant parts with complex structures because of its excellent casting performance, machinability, wear resistance and wear reduction, simple melting ingredients and low cost.

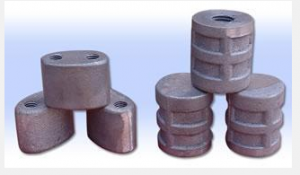

3. Malleable iron. The content of carbon and silicon in it is low, which is the result of long-time secondary high-temperature annealing of white cast iron billet.

4. Ductile iron. Ductile iron is cast from molten iron, and a certain amount of silicon iron and magnesium spheroidizing agent will be added in the casting process. It can spheroidize graphite. Thereby improving yield strength, tensile strength, impact toughness and plasticity. Ductile iron is widely used in industry.

White cast iron

Gray cast iron

Malleable iron

Ductile iron

Post time: Sep-13-2022