-

Record Kralle

The Grip collars are fixed outside of the shielded couplings. They can strengthen the pressure which pipes bear. The dimensions can be from DN50-DN300. The bear pressure DN50-DN100 10 bar, DN150 -DN200 5bar, DN250-DN300 3bar.

-

Grip Collar

The Grip collars are fixed outside of the shielded couplings. They can strengthen the pressure which pipes bear. The dimensions can be from DN50-DN300. The bear pressure DN50-DN100 10 bar, DN150 -DN200 5bar, DN250-DN300 3bar.

-

Ductile Iron Pipes

The ductile iron pipes are manufactured according to ISO2531/EN545/EN598/NBR7675 international standard. Ductile cast iron is a kind of alloy of iron, carbon and silicon. During production process, we carry out tests on line strictly and test items includes: hydraulic pressure, cement lining thickness, zinc spraying thickness, bitumen coating thickness, dimension test, impressing test and so on. Especially, we have the most advanced X-ray detector to test wall thickness of each pipe precisely so that we could ensure pipes quality conform to ISO2531 standard.

External zinc spraying (≥130g/㎡) and bitumen coating (≥70um) conform to ISO8179 standard. Epoxy, polyurethane and polye the thylene can be supplied according to clients’ requirments.

Internal cement mortor lining conforms to ISO4179 standard and the cement mortor is firm, dense, smooth and strong adhension. High-Aluminum cement, Portland cement, Sulphate-Resistance cement, epoxy resin, epoxy ceramic for inside lining.

-

Ductile Iron Fitting

The ductile iron pipes are manufactured according to ISO2531/EN545/EN598/NBR7675 international standard. Ductile cast iron is a kind of alloy of iron,carbon and silicon. During production process, we carry out tests on line strictly and test items includes: hydraulic pressure, cement lining thickness, zinc spraying thickness,bitumen coating thickness, dimension test, impressing test and so on. Especially, we have the most advanced X-ray detector to test wall thickness of each pipe precisely so that we could ensure pipes quality conform to standard.

Coating: Epoxy Resin Paints&Powder Coating, bitumen coating.

-

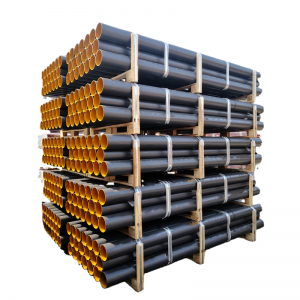

EN877 KML Cast Iron Pipe Packages

KML drainage pipe and fittings are used for grease-containing waste water of professional kitchens and similar facilities.

Outside coating: Bear a spray zinc coating with an areal density of min 130g/㎡, and above that an epoxy cover of a minimum of 70um.

Inside coating is orche-coloured epoxy.A double layer of resin epoxy with a total layer thickness 240um.

KML fittings are coated inside and outside with a high quality powder epoxy of least 120um.

- Email Support plumbingsales01@sjzmetal-electric.com

- Call Support

0086-13833199589

0086-311-86031515